Ford Motor Company has joined forces with 3M and GE Healthcare by lending its manufacturing and engineering expertise to speed up production of urgently needed medical equipment and supplies for healthcare workers, first responders and patients fighting coronavirus.

The company is working with 3M to increase the manufacturing capacity of their Powered Air-Purifying Respirator (PAPR) designs and also to develop simpler units by using off-the-shelf items to meet the surge in demand of such items used by health care workers.

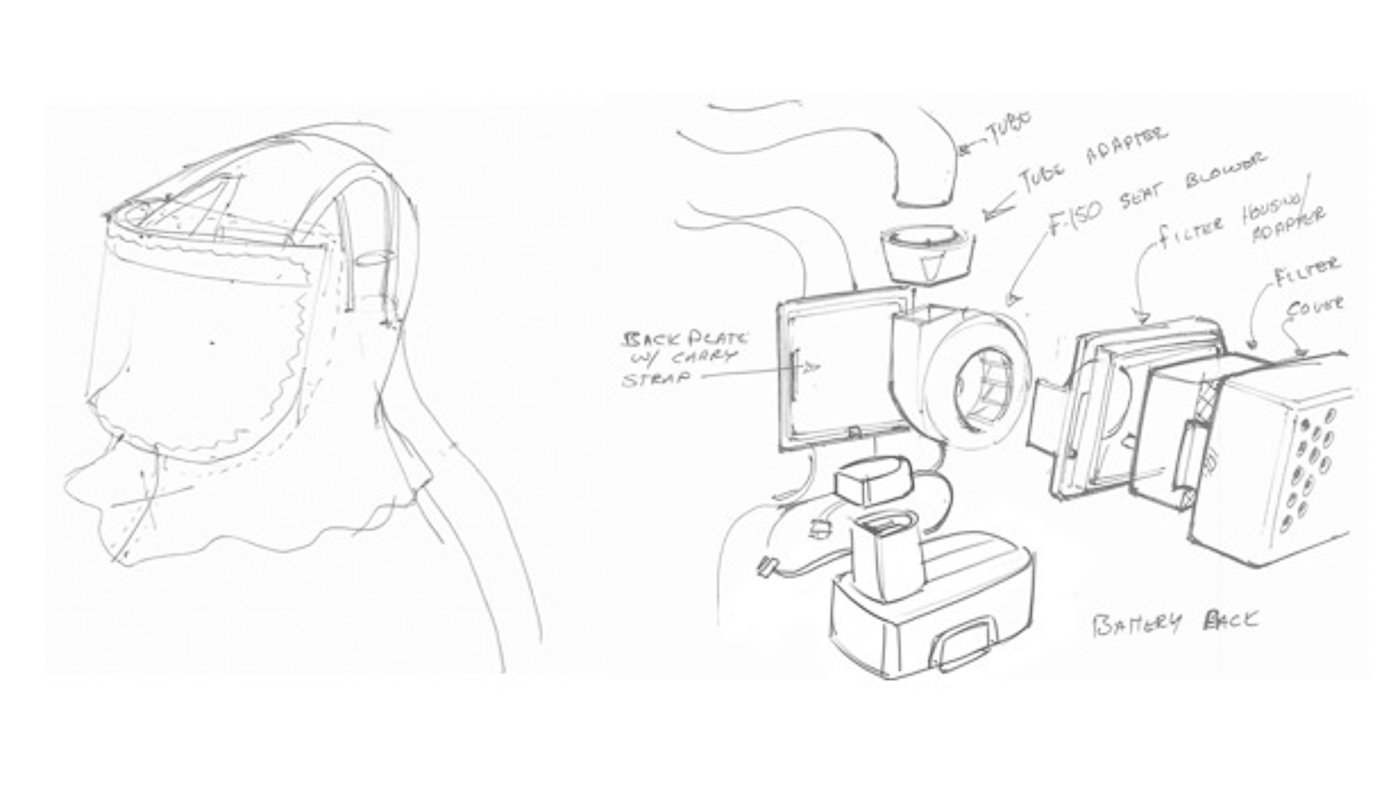

Pictured above is the blueprint of the easy-to-build respirator for the front liners of the Covid-19 battle as shared by Ford North America Product Communications Manager, Mike Levine on Twitter. According to him, the respirator’s design prompted the initiative to be called “Project Apollo”.

Among them include fans from the Ford F-150’s cooled seats for airflow, 3M HEPA air filters to filter airborne contaminants such as droplets that carry virus particles and battery packs from portable power tools to power these respirators for up to eight hours.

In addition, Ford plans to produce over 100,000 face shields per week and leverage its in-house 3D printing capability to manufacture components used to produce personal protective equipment.

“Working with 3M and GE, we have empowered our teams of engineers and designers to be scrappy and creative to quickly help scale up production of these vital equipment,” said Ford President and CEO, Jim Hackett.

In China, Ford of China joint venture partner Jiangling Motors donated 10 specially-equipped Transit ambulance vans to hospitals in Wuhan, where the coronavirus outbreak began.

IMAGE GALLERY