The Malaysia Automotive, Robotics and IoT Institute (MARii) today announced its collaboration with local tech firm to produce Personal Protection Equipment (PPE) for the front liners in the fight against the COVID-19 pandemic.

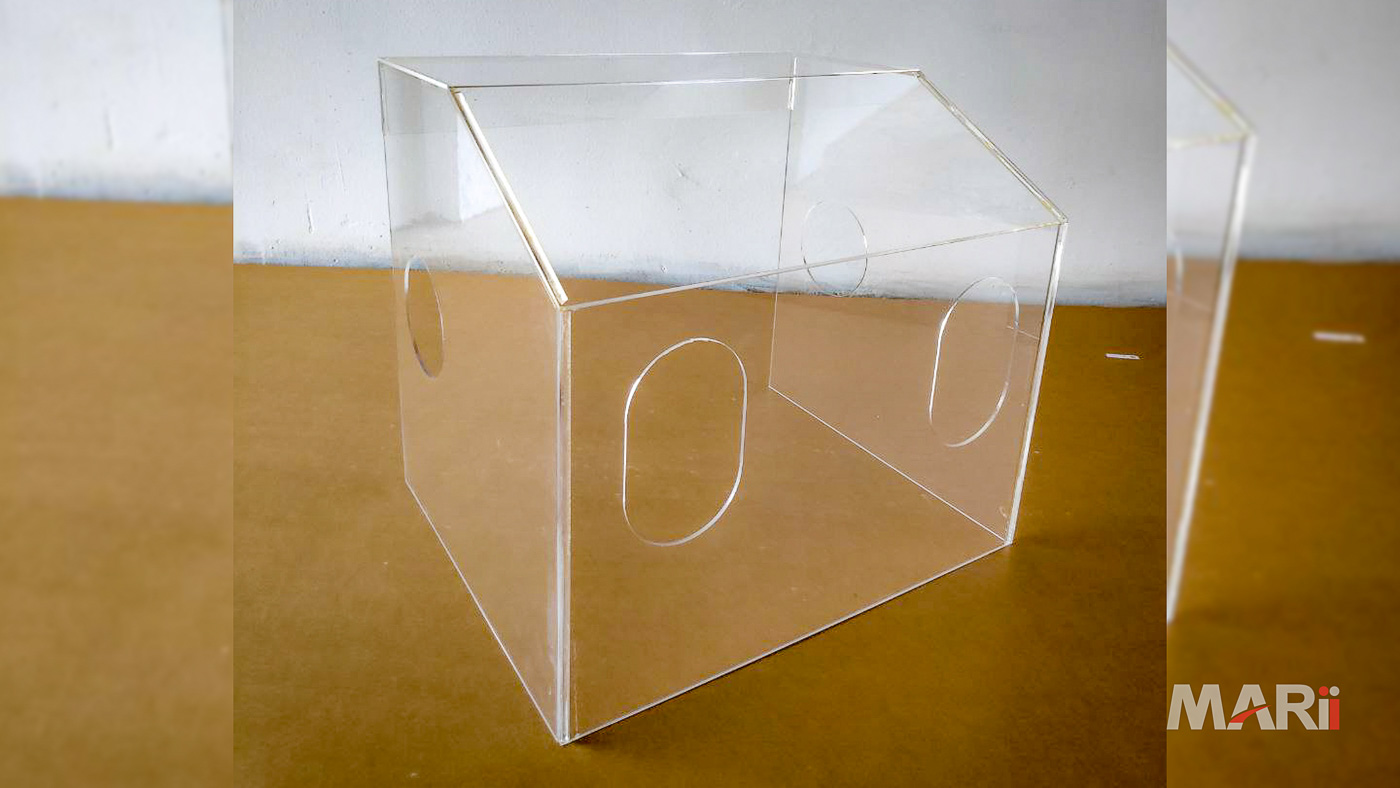

The partnership will manufacture face shields and intubation boxes using the laser cutting process, which uses a precise laser beam to cut, weld, mark and heat plastic into the desired shape.

The laser cutting process results in faster and more efficient production, without the need of additional tooling. The flexibility of the process also makes redesigns and modifications of products easy and instant.

The laser cutter can also use easily-sourced materials such as Perspex and acrylic in production, which makes it especially helpful given the restrictions placed on the logistics sector.

Usage of laser cutting machines can also reduce the need of manpower, as the machines require minimal operational supervision. As a side benefit, the risk of virus transmission during production is also lowered due to a simpler process workflow and minimised human contact.

MARii CEO, Dato’ Madani Sahari explained, “These benefits make laser cutting a highly viable process in situations such as COVID-19, where single use products face a huge spike in demand.

“MARii’s technology network has opened up opportunities for quick action to be taken for the PPE supply issue, and we hope more solutions can be developed to address other issues surrounding the pandemic,” he added.

According to Dato’ Madani, the partnership expects 1,000 face shields and 50 intubation boxes to be made in a day.

Aside from MARii, many companies capable of manufacturing, as well as the local 3D-printing DIY scene lead by KakiDIY, has also taken the initiative to produce single-use PPE for our front liners.