Every bit counts in the fight against the Covid-19 pandemic, and Mercedes-Benz is offering its expertise and technology for the production of medical equipment via 3D printers, where much-needed components can be made urgently.

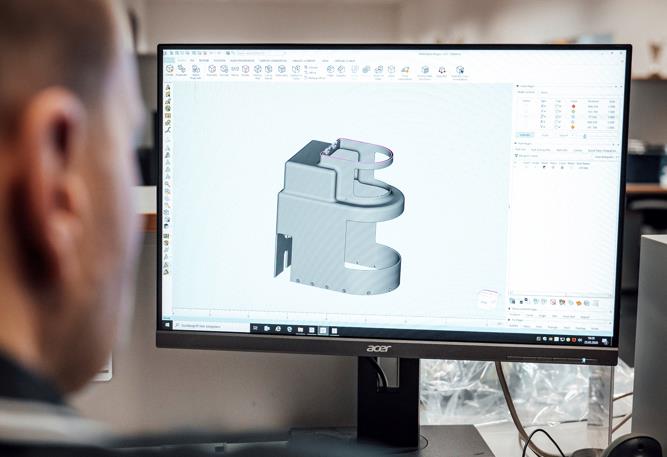

Mercedes-Benz typically produce up to 150,000 plastic and metal components each year utilising 3D printing machines for prototype construction and small-series production run, but the capacity can now be channelled entirely for medical purposes.

“With our highly competent team and years of experience in 3D printing technology, we are ready to make our contribution to the production of medical devices,” says Jörg Burzer, Member of the Board of Management of Mercedes-Benz AG, Production and Supply Chain. “To this end, we are also in contact with the state government of Baden-Württemberg. Our expertise and specialist knowledge is available for production; now it is up to the medical technology sector to contact us. Our 3D printers are definitely available.”\

In additive manufacturing, digitally developed components are built up layer by layer in a ‘printer’. The raw materials used include plastic and metal powders or resins which are fused by an energy source – usually one or more lasers. Once a layer is finished, a new layer is applied automatically and the solidification process starts again. This process is repeated until a three-dimensional component is created.